Description

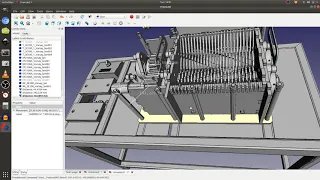

Take a look at the design of the pro shredder from Precious Plastic. Download the STEP and use FreeCAD STEP import - https://wiki.opensourceecology.org/wiki/Precious_Plastic_Shredder#Github_Download

About 6" separation between rotors, shafts are 1.7". A gear transfers the motion from one shaft to another.

What can be replaced with 3D prints? We're determining if 3D printed bearings and geardowns could do this. While we know that a 1kW+ motor is required, we are doing both the kW-scale motor and a small motor like in a cordless drill, 100W, with 1000x geardown to achieve about 30 kg-M torque. Study the torque requirements at https://wiki.opensourceecology.org/wiki/Shredder_Drive

You can follow progress at https://wiki.opensourceecology.org/wiki/Open_Source_Shredder.

-----------------

What you see here at Open Source Ecology is an ambitious open source project for the common good. Join our development team:

http://opensourceecology.org/wiki/OSE_Developers

We run One Day Extreme Build workshops in many locations. Please put yourself on our map if you'd like us to host a workshop near you:

https://microfactory.opensourceecology.org/request-a-workshop/

Take a minute to subscribe to our email newsletter (updates, workshops, etc): http://bit.ly/1LtcM44